An Automated Syringe Assembly and Filling Production Line represents a significant greatment for medical device manufacturers. Designed to streamline the assembly and filling of syringes, it combines precision, speed, and reliability, allowing companies to maintain high standards while increasing production capacity. Many manufacturers turn to an Automated Syringe Assembly and Filling Production Line Factory to access these capabilities and integrate automation seamlessly into their production processes.

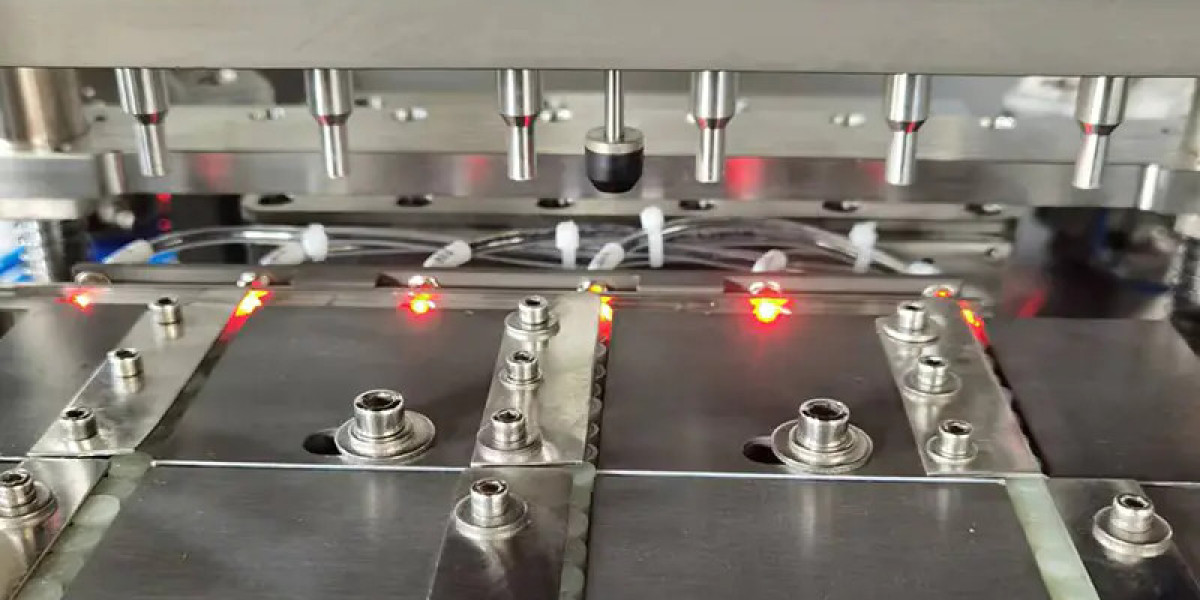

One of the main advantages of using such a production line is its precision and accuracy. The system is equipped with great robotic mechanisms and control systems that handle tiny syringe components with micron-level precision. This reduces human error during assembly and filling, ensuring that every syringe meets strict quality requirements. For manufacturers, this level of accuracy is critical, especially when producing devices intended for medical use where consistency cannot be compromised.

Another key aspect is efficiency and productivity. By automating repetitive tasks, an Automated Syringe Assembly and Filling Production Line can operate continuously, significantly reducing labor requirements and speeding up production cycles. High-speed conveyors and robotic arms enable a smooth, uninterrupted workflow, allowing manufacturers to meet tight deadlines without sacrificing quality. The real-time monitoring systems included in most modern production lines help detect potential issues early, preventing costly downtime and optimizing overall efficiency.

Versatility is also an important feature. An Automated Syringe Assembly and Filling Production Line Factory often offers modular designs that can be customized for different syringe types, sizes, and materials. Whether working with plastics, metals, or delicate biomaterials, manufacturers can adapt the system to their specific production needs. This flexibility makes it possible to handle multiple product variations on a single line, reducing the need for separate setups and minimizing changeover times.

Quality assurance is another area where automation shines. Most systems include vision inspection tools and quality control algorithms that detect defects or deviations immediately during the assembly and filling process. This ensures that only syringes meeting the required standards leave the production line. Partnering with an Automated Syringe Assembly and Filling Production Line Factory allows manufacturers to implement these quality checks efficiently, improving reliability and reducing the risk of recalls or regulatory issues.

Integrating an Automated Syringe Assembly and Filling Production Line into medical device manufacturing brings measurable improvements in accuracy, efficiency, and product quality. For companies looking to enhance their production capabilities, working with a reputable Automated Syringe Assembly and Filling Production Line Factory provides the expertise and technology needed to achieve these benefits. From precision assembly to high-speed filling and comprehensive quality control, automation offers a practical solution for modern syringe manufacturing needs.