IMARC Group’s “3D Printer Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” offers a detailed and practical guide for entrepreneurs and businesses looking to understand how to start an 3D printer manufacturing plant effectively. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a manufacturing plant successful unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as 3D printer manufacturing plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

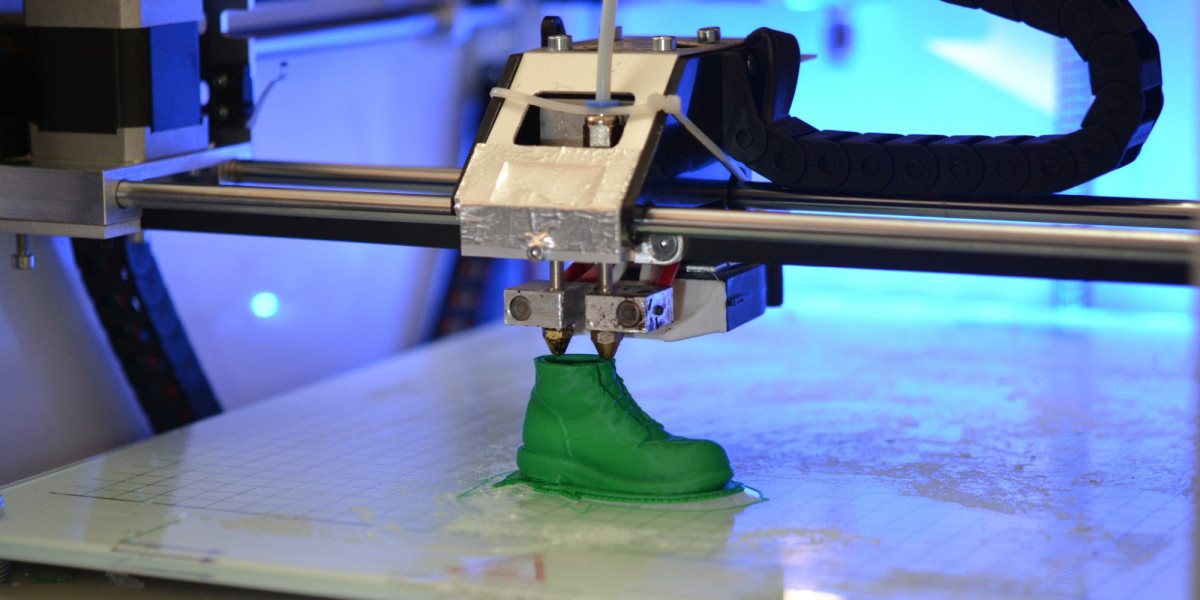

What is 3D Printer?

A 3D printer is an additive manufacturing device that creates physical objects by depositing material layer by layer based on a digital design. Unlike traditional subtractive methods that cut material away, 3D printing builds items from the ground up, enabling complex geometries, rapid prototyping, customization, and efficient small-batch production. Common materials include plastics, resins, metals, and even composites, making 3D printers valuable across industries such as aerospace, healthcare, automotive, consumer goods, and education.

Request for a Sample Report: https://www.imarcgroup.com/3d-printer-manufacturing-plant-project-report/requestsample

Market Trend and Drivers of 3D Printer:

The 3D printer industry is experiencing strong growth driven by advancements in material science, faster printing technologies, and expanding industrial adoption. Key trends include the rise of metal additive manufacturing, increased automation and AI-powered optimization, and growing demand for mass customization in sectors like medical devices and automotive manufacturing. The shift toward decentralized production and local manufacturing is further accelerating adoption, as companies seek supply-chain resilience and cost-effective prototyping. Sustainability is also a major driver, with organizations leveraging 3D printing to reduce waste and energy usage compared to traditional manufacturing. Additionally, lower hardware costs and more user-friendly software are making 3D printing accessible to small businesses, hobbyists, and educational institutions.

Key Aspects to Set Up a 3D Printer Plant:

- Location to Setup Plant: Choosing a strategically accessible and cost-effective site ensures smooth operations and distribution.

- Market Research: Analyzing industry demand, competitors, and customer needs guides informed decision-making.

- Plant Layout: Designing an efficient layout optimizes workflow, safety, and production capacity.

- Construction and Infrastructure: Building the facility with proper utilities and structural support enables reliable manufacturing.

- Equipment/Machinery Procurement: Selecting and purchasing the right machinery ensures high-quality and consistent production output.

- Documentation and Licenses: Securing required permits and legal documents ensures compliance with regulatory standards.

- Cost Analysis: Evaluating all expenses helps determine financial feasibility and long-term profitability.

Requirements to Set Up a Facility:

- Funds: Adequate capital is essential to cover construction, machinery, labor, and operating costs.

- Machinery: Proper equipment is required to produce 3D printers efficiently and at scale.

- Land: Sufficient land is needed to house manufacturing, storage, and administrative spaces.

Types of Costs for Setting Up a 3D Printer Factory:

- Land, Location and Site Development Cost: These costs cover acquiring and preparing the site for construction and operations.

- Plant Layout Cost: Expenses related to designing an efficient and compliant facility layout.

- Machinery Requirements and Costs: Includes purchasing, installing, and maintaining essential production equipment.

- Raw Material Requirements and Costs: Costs of sourcing materials required for manufacturing 3D printers and components.

- Packaging Requirements and Costs: Expenses for packaging materials and processes for safe product handling.

- Transportation Requirements and Costs: Covers logistics for inbound materials and outbound finished goods.

- Utility Requirements and Costs: Includes electricity, water, HVAC, and other essential operating utilities.

- Human Resource Requirements and Costs: Costs related to hiring, training, and maintaining qualified staff.

Project Economics:

- Capital Investments: Total upfront spending required to establish the manufacturing facility.

- Operating Costs: Recurring expenses needed to run daily manufacturing operations.

- Expenditure Projections: Estimated future spending forecasts based on production plans.

- Revenue Projections: Expected income generated from selling 3D printers and related products.

- Taxation and Depreciation: Financial considerations involving tax obligations and asset value depreciation.

- Profit Projections: Anticipated earnings after deducting all operational and financial costs.

- Financial Analysis: A comprehensive evaluation of costs, revenues, and returns to assess overall project viability.

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

- Plant Setup

- Factory Audit Services

- Factory Setup Services

- Regulatory Approvals and Licensing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)