High-Density Polyethylene (HDPE) sheets are recognized as a go-to material in different sectors. This is because these sheets exhibit a mix of features like toughness, resistance to chemicals, and ecological friendliness. In theory, HDPE sheets are made of a single thermoplastic polymer which can tolerate harsh conditions. This, in practice, means they can be used in a wild range of sectors, starting with construction, continuing with agriculture, and ending with industrial manufacturing. When inclined to opt for HDPE sheets for your work, it is an absolute must to get hold of good-quality and tailored-to-your-needs HDPE sheet manufacturers. In fact, using HDPE sheets has become a trend that points out their importance as dependable, cheap, and green solutions for harsh environments.

Core Properties and Benefits of HDPE Sheets

HDPE sheets boast their impressive physical and chemical properties. These sheets are quite light, but at the same time, extremely strong in terms of impact. What’s more, they resist all kinds of corrosion, moisture, and chemicals, hence can work in any environment where metals or other plastic materials are susceptible to degradation. Besides that, HDPE sheet manufacturers are UV stabilized. So, these sheets don't lose their properties even when they are exposed to the sun for a long period of time. This is a form of insurance that the product will last for years with small or no maintenance and this translates to a great deal of money that will not need to be spent over the lifetime of the product. The fact that the product is completely safe also paves the way for its usage in food processing, potable water storage, and healthcare sectors (meaning that HDPE product applications are further extended).

Diverse Applications Across Industries

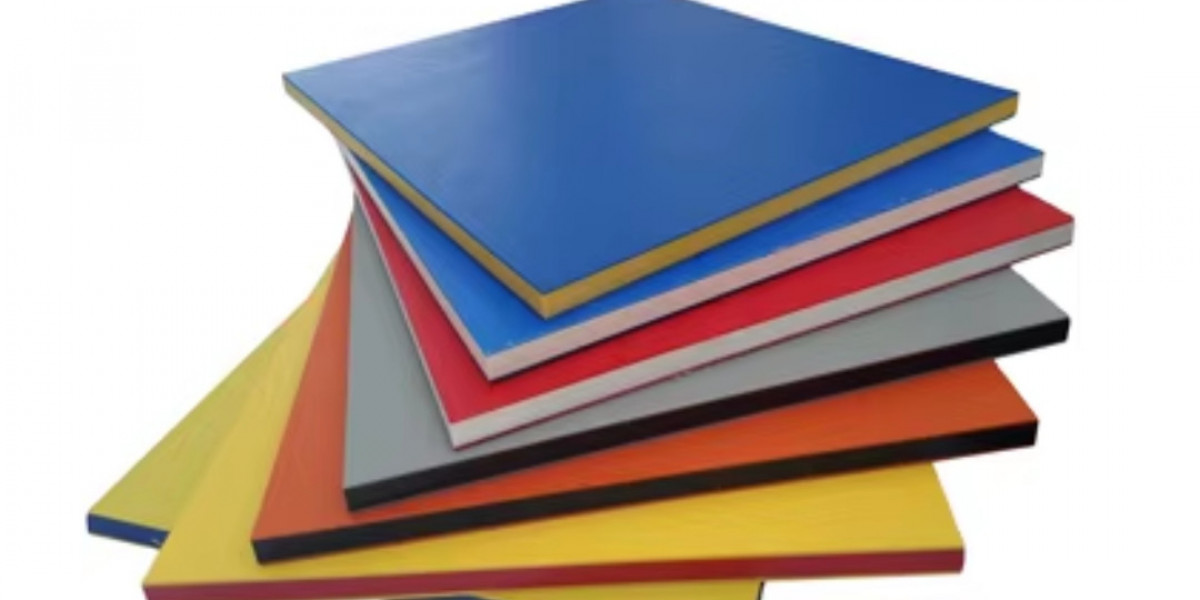

HDPE sheets are designed to be versatile enough to cover practically any industrial need. Therefore, in raising buildings, they are regularly employed. They are usually utilized as vapor preventer, liner for water reservoir, and shelter from nature elements. As a result of HDPE's resistance against chemicals and robustness, horticulture has also been able to take advantage of it well. So, agricultural films, silage liners, and irrigation systems have become the farmers’ new/modern tools. Marine industries are making use of HDPE sheets for the production of docks, floating barriers, and boat hulls as these products are resistant to saltwater. HDPE sheets in industry are transformed into various products like tanks, conveyor systems, and machine guards, etc. What is more, due to the fact that the materials used can be recycled and have no harmful effects on human beings, they are considered to be one of the safest materials that are allowed to come in direct contact with food or drinking water. Being able to personalize not only sizes but also colors and textures of the surfaces has made the material even more popular among those sectors that are so different from each other yet the same in that aspect.

Selecting the Right HDPE Sheet for Your Needs

Choosing a right HDPE sheet cannot be a hasty decision. It depends on the factors like thickness, size, color, surface finish, and even environmental exposure. Usually, thicker sheets help the user to get more impact resistance and also structural stability in a popular application of heavy load. To keep the materials under sunlight for a long time without degradation, UV-stabilized HDPE sheets are the preferred choice. If there is any chemical exposure, characterizing the levels will be the determining factor for the choice of the HDPE grade, with a number of specialized formulations available for the hardest substances. The most helpful and friendly conversation with sheet manufacturers will lead to a smooth move in confirming our needs in the product and actualizing our expectations. The right choice of work means not only a warranty for performance at its best, but also the maximum lifespan and the ultimate return of money to be expected from the same material piece.

Advantages Over Traditional Materials

In contrast to standard kinds of materials such as wood, steel, or concrete, HDPE Supplier sheets show a lot of advantages which may be listed as follows. Because of its corrosion and moisture resistance, HDPE is free from continuous maintenance, which, in turn, is the main source of saving cost and time. Due to its being light in weight, the performance of handling, the in-between transportation, and the concluding installation become smoother, easier, and less tiresome, especially if the project is of large-sized. The high impact resistance that HDPE has is what lasts it to be strong under heavy load and shock conditions. What is more, HDPE is an eco-friendly product since it is recyclable and many manufacturers of HDPE sheets produce their sheets from recycled material in this way they contribute to environmental sustainability. And, moreover, HDPE's advantages as a non-toxic material and its food-safe characteristics make it attractive for applications with direct human contact, e.g. food storage and processing. These benefits make HDPE sheets an intelligent and environment-friendly solution for a wide spectrum of applications.

Manufacturing, Customization, and Quality Assurance

The production of HDPE sheets aims at a high degree of precision by the use of extrusion techniques that help to regulate the thickness, dimensions, and quality of the surface. Top manufacturers of HDPE sheets have the provision and also offer the customization features at the customer’s option and requirements concerning color choice, the textured surfaced, and application of specific coatings such as anti-slip or antimicrobial for the layers. Custom fabrication allows sheets to progress smoothly into a specific project, whether that is in gaining decorative or functional advancements. Standard compliance of established manufacturers is what basically secures safety, uniformity, and durability to be the features of the products since quality assurance is the main concern and first priority. Such a dedication to quality and versatility are not only at par but also quite often go beyond the industry standards, thus providing dependable solutions for critical applications.

Conclusion

Briefly, HDPE sheet manufacturers producers are a highly versatile, long-lasting and eco-friendly material that has become a major player in a wide variety of industries. Their impeding against physical impact, chemical agents, and UV rays makes them possible for use in difficult environments, while their recyclability is a plus for sustainability objectives. As HDPE sheet vendors keep on innovating with new compositions, surface finishing and customization options, the future of HDPE sheets is, therefore, very bright and limitless. It is their mixture of strength, flexibility, and environmental-friendliness, which harnesses HDPE sheets as the core materials of the future industrial, agricultural, and ecological challenges.

Frequently Asked Questions

What makes HDPE sheets more durable than other plastics?

As a matter of fact, HDPE sheets are very resilient to impacts, they do not easily react with chemicals, are UV-stabilized, and are resistant to the ingress of moisture, which altogether makes them very long-lasting even in tough situations.Are HDPE sheets suitable for outdoor applications?

Definitely, the main feature of the UV-stabilized HDPE sheets is that they are very good at resisting long-term exposure to the sun without breaking down.Can HDPE sheets be recycled after they have been thrown away?

Absolutely. This is a very recyclable material, and so many sheets are being made from recycled plastic, thereby, supporting the eco-friendliness of the planet. What are the top industries that use HDPE sheets most of the time?

The top industries are Construction, Agriculture, Marine, Industrial Manufacturing, Environmental Management, and Food Processing.How do I determine the right thickness of HDPE sheets for my project?

First of all, the impact, load, and environmental conditions that the material will be exposed to have to be evaluated.Who is the largest supplier of HDPE Sheets?

Singhal Global PVT Ltd is one of the suppliers of HDPE sheets, but it is not necessarily the largest globally.Who is the largest exporter of HDPE Sheets?

Singhal Global PVT Ltd may be a recognized exporter of HDPE sheets, but it is not typically identified as the largest exporter worldwide.Who is the largest manufacturers of HDPE Sheets?

Singhal Global PVT Ltd is one of the manufacturers of HDPE sheets, but it is not generally recognized as the largest manufacturer worldwide.Can HDPE sheets be customized in size, color, and surface texture?

For sure. Most HDPE sheet producers provide different options for personalization depending on the needs of the project.Where can I find reputable suppliers of HDPE sheets?

You can search for certified manufacturers with a positive reputation in the industry and considerable experience; quite a few of them can be reached via online industrial suppliers or by making a direct inquiry.