In the ever-evolving world of modern manufacturing, precision, speed, and efficiency are no longer luxuries—they are necessities. As industries seek innovative ways to meet global demand and stay ahead of competition, advanced technologies such as laser beam welding machine are becoming indispensable. These machines are redefining how components are joined, ensuring flawless results even in the most demanding applications. Among the leading innovators driving this transformation is laserchina, a trusted name synonymous with reliability and cutting-edge solutions.

The Rise of Advanced Welding Technologies

Traditional welding methods, while useful, often come with limitations such as heat distortion, rough finishes, or slower processing times. As industries like automotive, aerospace, medical devices, and electronics require increasingly precise and durable welds, the need for advanced solutions has grown significantly.

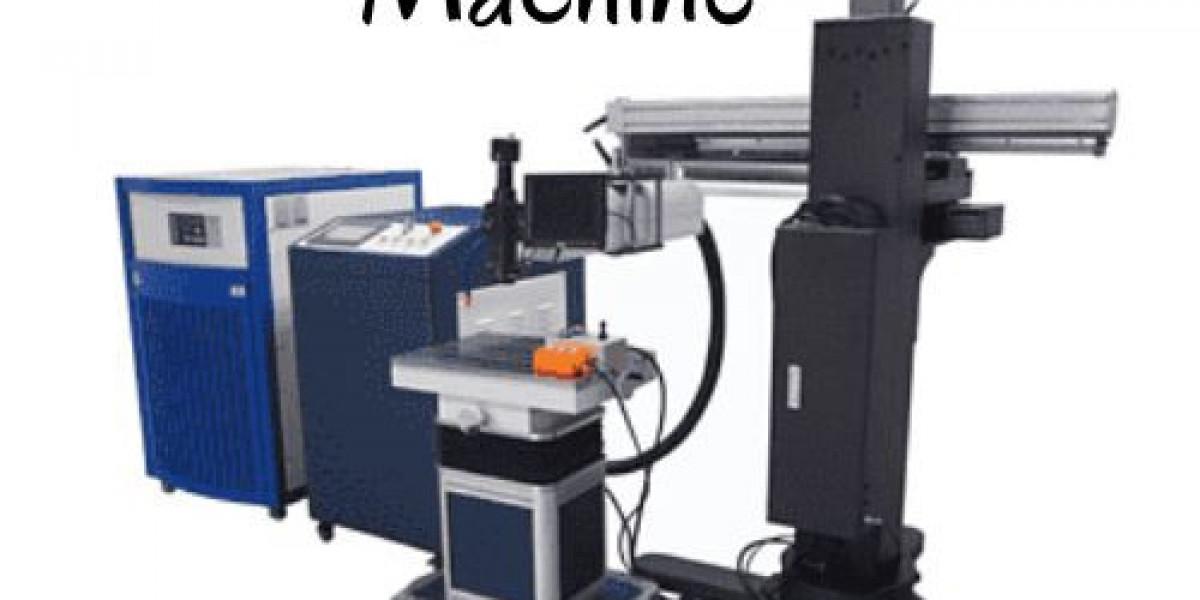

This is where laser welding technology comes in. Unlike conventional techniques, laser welding delivers pinpoint accuracy, minimal thermal impact, and superior speed. A laser beam welding machine allows manufacturers to achieve high-quality joints while reducing rework and waste, leading to improved overall efficiency.

What Sets a Laser Beam Welding Machine Apart?

The power of a laser beam welding machine lies in its ability to focus high-intensity light into a small spot, generating enough energy to fuse materials with unmatched precision. This results in welds that are cleaner, stronger, and more aesthetically appealing compared to other methods.

Some standout advantages include:

Exceptional precision: Ideal for micro-welding and intricate parts.

High-speed processing: Perfect for high-volume production.

Minimal distortion: Protects delicate components from heat damage.

Versatile applications: Works on metals like steel, aluminum, titanium, and even specialty alloys.

For companies looking to elevate production quality, adopting this technology is no longer optional—it is essential.

Industries Benefiting from Laser Welding

Laser welding is not confined to a single sector; its applications span multiple industries, each reaping unique benefits:

Automotive

The automotive industry relies heavily on welding for both structural and aesthetic parts. Laser beam welding machines help achieve lighter, stronger joints, essential for improving fuel efficiency and safety.

Aerospace

In aerospace, precision is critical. Laser welding ensures flawless seams in turbine blades, engine components, and structural parts, where even minor errors can be catastrophic.

Medical Devices

From surgical tools to implantable devices, medical products require welds that are both durable and biocompatible. Laserchina’s technology ensures sterile, reliable joints that meet strict regulatory standards.

Electronics

As devices get smaller and more complex, traditional welding struggles to keep up. Laser welding allows for fine, delicate joints in microelectronic components, ensuring both durability and performance.

Why Choose Laserchina for Welding Solutions?

In a marketplace full of options, laserchina stands out for its dedication to innovation, quality, and customer satisfaction. The company’s laser beam welding machines are engineered with state-of-the-art features, designed to meet the needs of both small-scale manufacturers and large industrial operations.

What makes laserchina a preferred partner?

Expertise: Years of experience in laser technology and industrial automation.

Customization: Tailored solutions to fit specific production needs.

Reliability: Machines designed for long-term performance with minimal downtime.

Support: Comprehensive training and after-sales service to maximize customer success.

By combining technical excellence with a customer-first approach, laserchina empowers businesses to harness the full potential of laser welding.

The Future of Manufacturing with Laser Welding

Looking ahead, the role of laser welding will only continue to grow. With rising demands for lightweight materials, miniaturization, and sustainable production methods, laser beam welding machines are set to become the backbone of modern manufacturing. Companies that adopt this technology early gain a significant competitive advantage by improving product quality, reducing costs, and accelerating production timelines.

Laserchina remains at the forefront of this evolution, ensuring that businesses across industries can achieve their goals with confidence.

Final Thoughts

As industries move toward smarter, faster, and more precise production methods, the value of advanced welding solutions cannot be overstated. A laser beam welding machine is more than just equipment—it is an investment in efficiency, quality, and the future of manufacturing.

By partnering with laserchina, businesses gain access to cutting-edge technology, unmatched expertise, and the assurance of working with a brand committed to excellence. Whether you are in automotive, aerospace, medical, or electronics manufacturing, the path to higher precision and productivity starts with laserchina’s solutions.