In the evolving world of chocolate production, the terms Chocolate Depositor and Gusumachinery often appear together, representing both a trusted brand and a crucial piece of processing equipment. This combination symbolizes the balance between efficiency and creativity in confectionery production, allowing manufacturers to consistently deliver products that meet diverse consumer expectations.

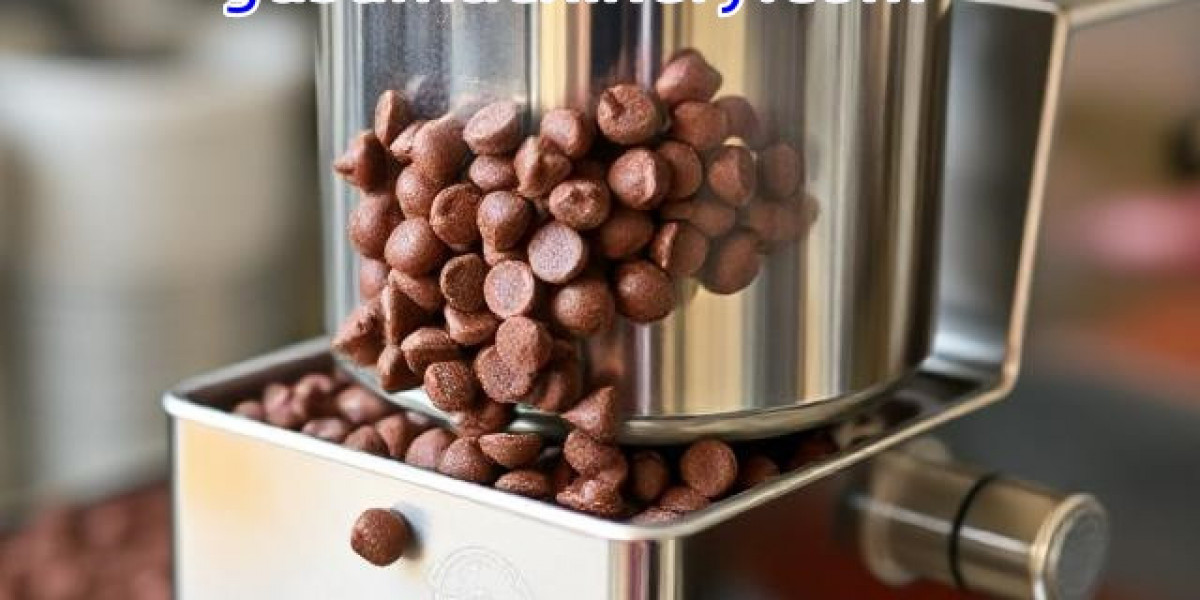

A chocolate depositor is more than a machine for dispensing chocolate into molds. It functions as a precision tool that ensures each piece has the correct weight, shape, and finish. This level of control is essential for businesses that rely on consistent quality across large production runs. By eliminating guesswork and reducing inconsistencies, depositors play a central role in shaping chocolate products that are uniform and reliable.

The advantages extend beyond accuracy. Modern depositor systems are designed to work seamlessly within broader production lines, supporting both automation and customization. Whether a factory produces filled chocolates, solid bars, or innovative seasonal designs, the depositor ensures flexibility without sacrificing operational flow. This adaptability is particularly valuable in a market that thrives on variety and constant innovation.

Operational efficiency is another defining factor. The depositor's ability to handle high volumes with steady precision reduces unnecessary interruptions, leading to streamlined processes. It helps maintain a rhythm that aligns with other machinery in the production line, ensuring that each stage connects smoothly. Such integration allows businesses to achieve more predictable outcomes while managing resources effectively.

Beyond performance, hygiene and durability also play a key role in the design of chocolate depositors. In a food production environment, equipment must meet strict cleanliness standards and withstand continuous use. Machines tailored for chocolate ensure easy cleaning and consistent operation, meeting both safety and efficiency requirements. This combination gives producers confidence that their investment will support long-term production needs.

For manufacturers, choosing the right depositor is not only a matter of immediate productivity but also of future growth. As consumer preferences shift, the demand for unique chocolate varieties increases. A well-designed depositor system allows producers to experiment with new recipes and formats, supporting innovation without disrupting established production. In this way, it becomes a bridge between tradition and modern creativity.

Those considering how to bring their chocolate production to a new level of precision and flexibility can benefit from seeing such equipment in action. Instead of stopping at theory, one simple step can provide practical insight. To explore how this technology supports real-world confectionery manufacturing, visit https://www.gusumachinery.com/news/industry-news/chocolate-depositors-features-benefits-trends-and-more.html today. The next idea for your production line may begin with that single click.