Introduction:

At Auto Die Cast (India), we have been making strong and accurate metal parts for many years. When it comes to creating high-quality products, the process we use is very important. Two of the most common methods in the industry are Pressure Die Casting and High Pressure Die Casting.

Both of these methods are used by Pressure Die Casting Manufacturers around the world, from Pressure Die Casting in Delhi to big Die Casting Manufacturers in India. They are popular because they can produce parts that are exact in size, have smooth surfaces, and are strong enough for heavy use.

In this content, you will learn what each method is, how they work, how they are different, and which one might be the right choice for your project. This way, whether you are working with High Pressure Die Casting Suppliers or Pressure Die Casting Suppliers, you will have a clear idea of which method suits your needs best.

What Is Pressure Die Casting? – Overview & Working Process

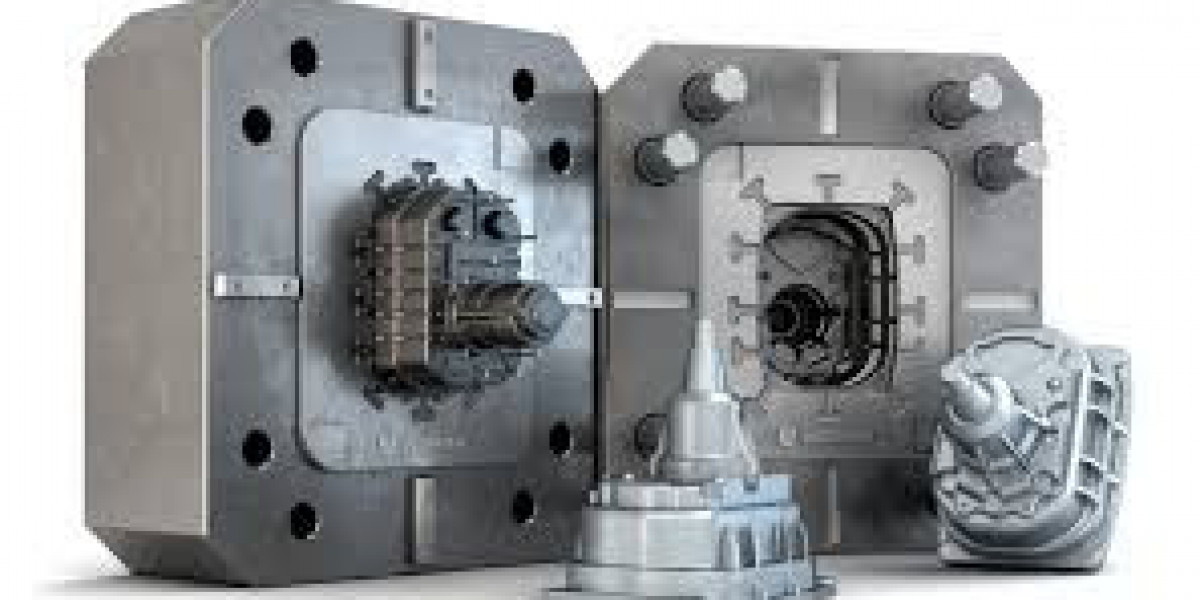

Pressure Die Casting is a method where melted metal is pushed into a mold using pressure. This mold is made of strong steel and is shaped to match the part we want to make. Once the metal cools down and hardens, the mold is opened, and the part is removed.

How it works:

The chosen metal, such as aluminum, zinc, or magnesium, is melted in a furnace.

The melted metal is pushed into the mold using a machine.

The metal cools and becomes solid.

The mold opens, and the part comes out.

This process is great for making many parts of the same shape and size. Pressure Die Casting in India is used in many industries like automotive, electronics, and machinery. Many Brake Drum Manufacturers also use this process because it makes parts that are both strong and accurate.

What Is High Pressure Die Casting? – Overview & Working Process

High Pressure Die Casting is very similar to normal Pressure Die Casting but uses much more force to push the metal into the mold. This extra pressure helps the melted metal fill even the smallest details of the mold very quickly.

How it works:

The metal is melted until it becomes liquid.

It is pushed into the mold at very high pressure, sometimes more than 10,000 psi.

The pressure stays until the part is solid.

The mold opens, and the part is removed.

This method is very popular among High Pressure Die Casting Manufacturers because it allows them to make very detailed parts quickly. High Pressure Die Casting Exporters supply these parts to industries like cars, airplanes, and electronics, where exact measurements and high quality are very important.

Key Differences Between Pressure Die Casting and High Pressure Die Casting

Even though both processes make metal parts by pushing melted metal into a mold, there are a few important differences:

Pressure Used:

Normal Pressure Die Casting uses less pressure.

High Pressure Die Casting uses much higher pressure to fill the mold.

Speed:

High Pressure Die Casting is faster and better for making a lot of parts quickly.

Detail:

High Pressure Die Casting can make more complex and detailed parts.

Cost:

For small batches, normal Pressure Die Casting can be cheaper.

For very large batches, High Pressure Die Casting is more cost-effective.

Knowing these differences can help when talking to Pressure Die Casting Manufacturers in Delhi or working with Die Casting Suppliers in India.

Advantages of Pressure Die Casting

Here’s why many Pressure Die Casting Suppliers and Brake Drum Manufacturers choose this method:

Good for Medium Production: Works well for making a medium number of parts.

Accurate Shape: Parts come out very close to the exact size needed.

Works with Many Metals: Suitable for aluminum, zinc, and magnesium.

Strong and Durable: The parts last a long time.

Advantages of High Pressure Die Casting

High Pressure Die Casting Suppliers choose this method for several reasons:

Perfect for Big Orders: Can make a large number of parts in a short time.

High Detail: Can produce very thin and detailed shapes.

Strong Parts: Good for heavy-duty use.

Less Finishing Work: Parts often come out smooth and ready to use.

Choosing the Right Casting Method for Your Project

When deciding between Pressure Die Casting and High Pressure Die Casting, think about:

How Many Parts You Need: Medium amounts may be better with normal Pressure Die Casting; large amounts are better with High Pressure Die Casting.

How Complex the Part Is: Very detailed designs may need High Pressure Die Casting.

Your Budget: Smaller budgets may work better with standard Pressure Die Casting.

End Use of the Part: Heavy-duty or highly precise parts may need High Pressure Die Casting.

Talking to Die Casting Manufacturers in India, High Pressure Die Casting Exporters, or Pressure Die Casting in Delhi will help you choose the best option for your needs.

Conclusion

Both Pressure Die Casting and High Pressure Die Casting are excellent ways to make strong, accurate, and long-lasting metal parts. The choice depends on how many parts you need, how complex they are, and your budget.

At Auto Die Cast (India), we have the skills and experience to produce both types of casting at a high standard. Whether you need a small batch or large-scale production, we can provide the best solution for your business.

Contact us today to get the right casting method for your product and ensure top-quality results every time.