CNC machines, or Computer Numerical Control machines, play a vital role in modern manufacturing. They use computer programming to control tools with high precision, allowing the creation of detailed parts that meet exact specifications. Industries such as aerospace, automotive, and medical equipment rely on CNC machines to increase production efficiency and accuracy. CNC machine repair Australia automate tasks that were previously done by hand, transforming manufacturing methods. They manage large production volumes while maintaining quality, making them essential for businesses with tight schedules or uniformity needs. They also work with metals, plastics, and composites, meeting diverse production demands.

Common CNC Machine Issues

CNC machines are complex but still face operational problems. Issues often appear with regular use. Tool wear is common—cutting tools dull over time, reducing accuracy. Regularly checking and replacing tools keeps machining precise.

Alignment problems can happen when machine axes slip out of line. This reduces machining accuracy and produces out-of-spec parts. Fixing alignment issues quickly avoids production slowdowns.

Power supply issues can trigger machine failures or odd behaviors. A steady power source lowers this risk. If you hear vibrations or strange noises, act fast—they signal mechanical or electrical faults that need attention to prevent bigger problems.

Machines Performing Well

Problems with software or outdated control systems also reduce machine efficiency. Update software and check compatibility for best results. Regular monitoring lets you catch issues early and keep CNC machines performing well.

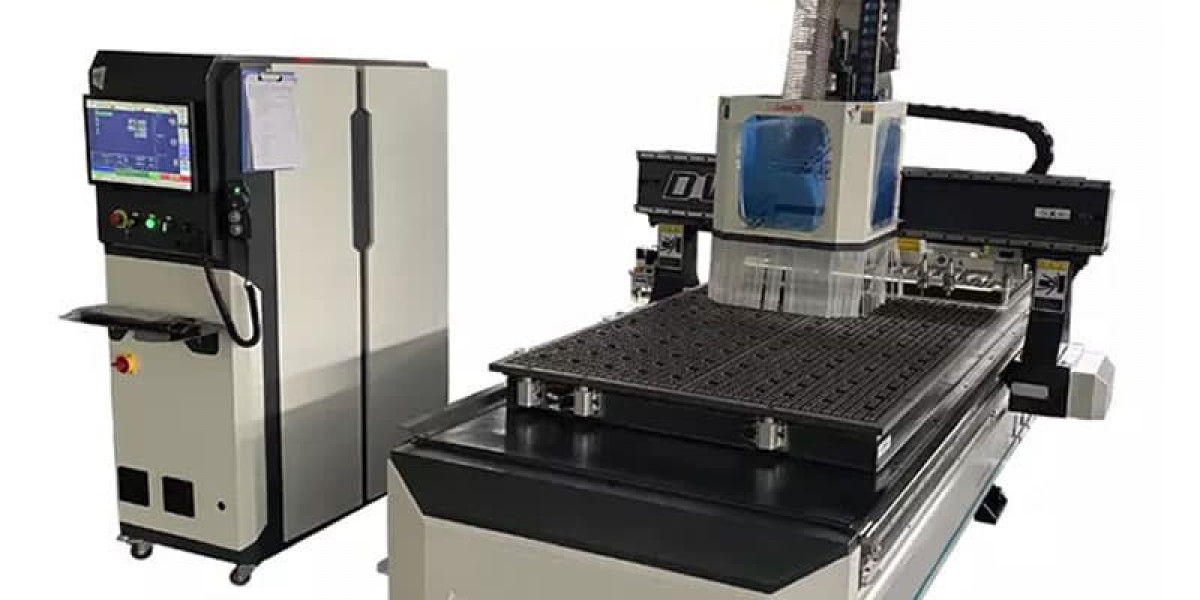

A typical CNC machine has a control panel, spindle, cutting tools, and axes, all critical to its function. They perform milling, drilling, turning, and grinding with precise accuracy. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) integration enables smooth design-to-production workflows and boosts industrial efficiency.

CNC Machine Repair Services in Australia

Australia offers specialised CNC machine repair services for manufacturers. These services diagnose technical faults, replace parts, and recalibrate systems to restore machines. Repair providers use advanced diagnostic tools and industry knowledge to fix mechanical and software issues quickly.

Many Australian repair professionals work with various CNC machines, including mills, lathes, and grinders. Providers keep spare parts on hand to make quick repairs and reduce downtime. Some offer on-site repair, so you don't need to move machines to a workshop.

More service providers now offer tailored maintenance plans to keep machines in peak condition. They stay up-to-date on CNC technology and help clients upgrade parts as needed. Their expertise ensures Australian businesses maintain high productivity.

Choosing a Reliable Repair Service

When picking a CNC repair provider, check key factors to match your needs. Look for experience with different CNC machines and a strong record. Ask if they know your machine models—familiarity leads to faster, more accurate repairs.

Check if providers have advanced diagnostic tools and spare parts. Well-equipped providers fix issues faster and lower downtime. Fast response is vital for tight schedules; quick service keeps production moving. The reputation of a repair provider within the industry may provide further insight into the quality of service offered. Reviews, testimonials, and recommendations from other businesses can be helpful in gauging reliability.

It may also be valuable to inquire about additional services, such as on-site repairs or long-term maintenance plans, which can provide added convenience and help maintain equipment in optimal condition. Verifying certifications or training credentials further ensures the provider’s competency in handling complex repairs.

Preventive Maintenance for CNC Machines

Preventive maintenance ensures CNC machines remain operational and efficient over time. Consistent attention to critical components, such as spindles, cutting tools, and drive systems, helps to minimise wear and prevent unexpected breakdowns.

Cleaning and lubrication play a crucial role in maintaining optimal machine functionality, as accumulated debris or inadequate lubrication can hinder performance and increase the likelihood of damage. Monitoring coolant levels and ensuring the correct type of coolant is used also contribute to the longevity of these machines, as coolant plays a vital role in temperature regulation during operation.

Avoiding Costly Errors

Electrical systems require regular inspection to identify loose connections or potential faults, as these can lead to operational inconsistencies or downtime. Calibration of axes and tools is another essential aspect of preventive maintenance, ensuring machining accuracy and avoiding costly errors in production.

By adhering to a maintenance schedule tailored to the machine's usage and environment, businesses can effectively address minor issues before they escalate. Employing skilled technicians to conduct thorough inspections and upkeep further enhances the machine’s reliability and performance.

Importance of regular maintenance checks

Routine checks are essential for supporting CNC machine functionality and longevity. Inspecting components like spindles, cutting tools, and drive systems helps detect wear before major issues arise. Ensuring alignment accuracy and timely recalibration prevents errors and maintains production quality.

Proper lubrication and regular cleaning help maintain machine performance and prevent failures. Monitoring and using the correct coolant type reduces overheating risk and protects tools and materials. Electrical systems should be checked periodically to identify loose connections or wear that might cause inconsistencies. Stable power supply prevents downtime, while updated software ensures optimal performance for advanced models.

Implementing these checks as part of a well-structured maintenance plan allows businesses to optimise efficiency while extending the service life of their CNC equipment. Employing qualified technicians to perform these inspections ensures that all aspects of the machine are properly addressed.

Benefits of Used CNC machines for Sale Australia

Acquiring Used CNC machines for sale Australia presents an opportunity for businesses to enhance their production capabilities without incurring the higher costs associated with new equipment. These machines, often available at significantly reduced prices, allow manufacturers to allocate resources more efficiently, potentially enabling investment in other areas of operations.

Used CNC machines are frequently available in configurations that cater to various industrial applications, including milling, turning, and grinding. Many sellers provide detailed records of maintenance history, enabling buyers to assess the condition and performance of the equipment prior to purchase. In some cases, refurbished machines offer enhanced reliability, as they may have undergone thorough inspections and repairs to restore functionality.

Offering Flexibility

Another advantage is the shorter lead time for procurement compared to ordering new machines, which often require extended manufacturing and shipping periods. Used machines, being immediately available, can be deployed more rapidly to address production demands.

Furthermore, the availability of well-maintained second-hand equipment extends to both standard and specialised models, offering flexibility for businesses with unique machining needs. Finally, purchasing used machinery contributes to sustainable practices by extending the lifecycle of industrial equipment, reducing the environmental impact associated with the production of new machines and the disposal of older ones.

Where to Find Used CNC Machines in Australia

Locating used CNC machines in Australia is facilitated by a range of resources, including specialised dealers, auction houses, and online platforms dedicated to industrial equipment.

These channels often provide access to an extensive selection of machines suited to diverse manufacturing requirements, encompassing different brands, models, and configurations. Reputable dealers and resellers frequently perform thorough assessments of the machines they offer, ensuring functionality and reliability prior to sale.

In addition to traditional dealerships, public and private auctions present opportunities to acquire second-hand CNC machines, sometimes at competitive prices. Auction listings typically provide detailed descriptions and specifications, allowing potential buyers to identify machines that align with specific operational needs.

Different Price Ranges And Conditions

For buyers seeking immediate availability, online marketplaces represent a convenient option, offering a broad array of choices across different price ranges and conditions.

To ensure an informed purchasing decision, engaging with established and trustworthy sellers is crucial. Many sellers offer comprehensive documentation on previous maintenance, enabling buyers to evaluate the machine’s history and current state.

Depending on the seller, some machines may also include warranties or post-sale support, providing added reassurance to buyers. By utilising these resources, businesses in Australia can efficiently source suitable used CNC machines to meet production demands.

Tips for Evaluating Potential Purchases

Evaluating potential CNC machine purchases requires careful attention to several critical aspects to ensure that the equipment meets operational needs and offers value for investment.

A thorough visual inspection should be conducted to identify any visible signs of wear, such as worn components, misaligned axes, or excessive residue buildup, which may indicate improper maintenance or heavy usage. Examining the machine's operational capabilities is equally important; testing its performance under standard operating conditions can reveal hidden faults or inconsistencies.

It is recommended to verify the software version installed on the machine, as outdated software may lack compatibility with modern manufacturing systems or fail to support required functionalities.

Machine’s Upkeep

Maintenance records, if provided, should be reviewed meticulously, as they offer valuable insights into the machine’s upkeep, usage history, and any previous repairs. This information can help determine whether the equipment has been subjected to significant strain or neglect.

Engaging the expertise of a qualified technician for an independent assessment of the machine’s condition can further minimise the risk of purchasing equipment with underlying issues. Assessing the availability of replacement parts for the specific model is also advisable, as this impacts the ease and cost of future repairs. Such evaluations aid in selecting equipment capable of supporting consistent productivity.

Conclusion

Timely CNC machine repair Australia and consistent maintenance significantly enhance machine performance and extend service life. By addressing mechanical or software issues quickly, manufacturers avoid costly production delays and ensure ongoing accuracy and efficiency. Professional repair services deliver tailored solutions and reliable diagnostics, supporting business needs. Adopting a proactive maintenance plan reduces unexpected breakdowns, controls costs, and sustains operations. Purchasing well-maintained used CNC machines is a practical option for expanding capacity while managing budgets. Before buying, conduct thorough inspections and review maintenance records to confirm reliability and fit.

FAQs

Why is prompt CNC machine repair Australia essential in a fast-paced manufacturing environment?

CNC machine repair Australia prevents small mechanical or software issues from escalating into serious failures that can shut down entire production lines. In Australia's competitive and lean manufacturing sector, minimizing downtime directly impacts profitability, delivery schedules, and customer satisfaction. Quick intervention ensures continuity, avoids backlog, and keeps workflow disruptions to a minimum.

How does regular maintenance and timely repair affect the lifespan and efficiency of CNC equipment?

Consistent upkeep and early repairs help machines operate at peak efficiency, reducing wear and tear on key components. This not only extends the lifespan of costly equipment but also maintains the precision and accuracy that CNC machining demands. In industries such as aerospace.

Can delaying repairs on CNC machines affect workplace safety or regulatory compliance?

Absolutely. Ignoring small mechanical faults can lead to more serious hazards such as component failure or erratic machine behavior, posing risks to operators and the facility. Australian manufacturing businesses must also adhere to strict safety and machinery standards, and malfunctioning equipment could result in non-compliance penalties.

Related Business Listings |